Description

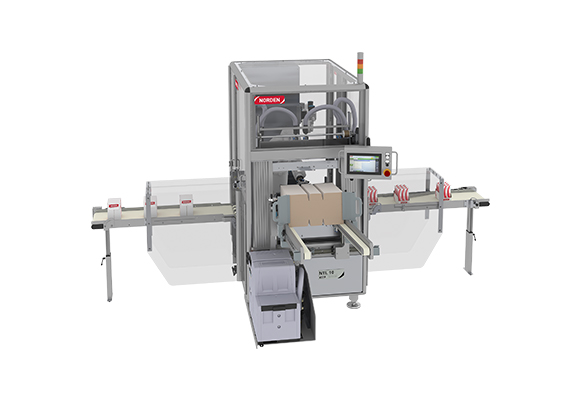

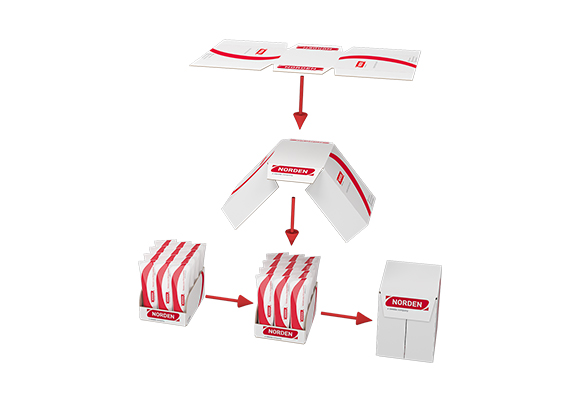

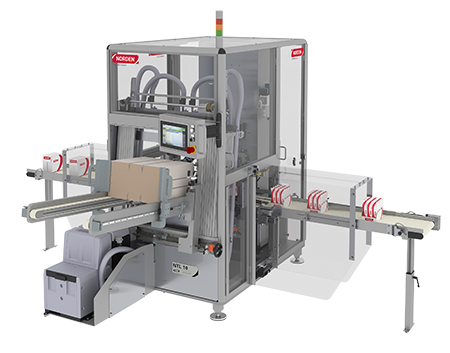

NTL 10, a machine that redefines the art of tray sealing. With the ability to fold and glue lids onto pre-packed trays at a rate of 10 trays per minute. As the trays move through the machine, the precise application of hot melt glue ensures a seamless seal, effectively safeguarding the contents while maintaining product integrity during transport. The addition of the lid means that the trays can be stacked onto a pallet like a normal box, ready for distribution. When its time to unpack, the lids are easy to remove and the tray is ready for display on any shelf with minimum effort. Packing your products in trays saves shelf space.

Setup the NTL 10 after the NTP 80 tray and case packer or with tray packers from other brands. Whether in a high-volume manufacturing environment or a fast-paced distribution center, this machine delivers consistent performance, day in and day out.