Looking for an efficient cartoning machine for tubes? Discover the NC 100

A production line is in constant motion, with products advancing in sequence, packaging formats changing from one order to the next and every adjustment needing to happen without breaking the pace that keeps output stable. In facilities where tubes are packed for pharmaceuticals, cosmetics, or food, the cartoning stage defines how efficiently products reach the final step before distribution.

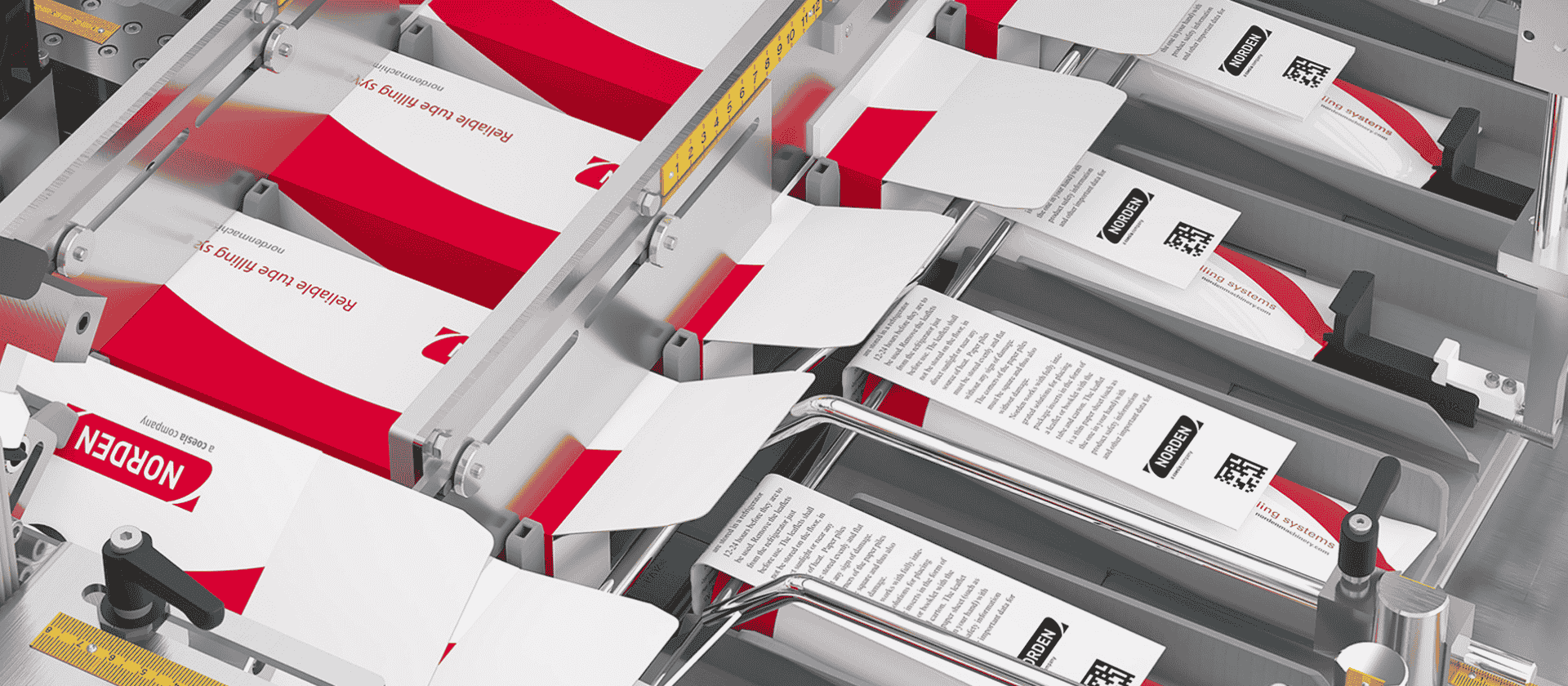

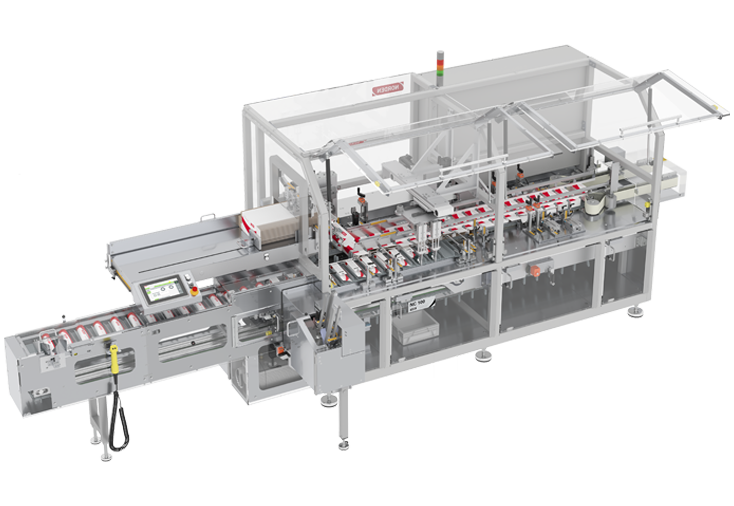

The NC 100 cartoning machine, developed by Norden, integrates carton erecting, filling and closing in a single platform. Its design combines performance, advanced flexibility and practical ergonomics, offering a solution built to meet the growing complexity of modern manufacturing.

Complete automation of the cartoning process

The cartoning machine NC 100 handles every phase of packaging, from the initial erection of flat cartons through filling and final closure. Operating in intermittent mode, this cartoner combines precise motion control with a production speed of up to 100 cartons per minute, ensuring stable operations even when volumes increase, maintaining precise handling across long production runs.

Its mechanical construction has been engineered for durability, delivering consistent performance in demanding environments such as pharmaceutical production, where accuracy and reliability are essential.

Cartoning machine with flexible configuration and rapid changeovers

Modern production rarely involves a single carton size or packaging style, and switching between different products can easily disrupt the pace of a line. The NC 100 addresses this challenge with a flexible structure that supports both leading and trailing edge carton erection, adapting smoothly to a wide variety of packaging formats.

With up to 50 pre-programmed formats ready to be activated at any moment, changeovers become exceptionally fast and controlled, keeping production continuous even when packaging requirements shift. This versatility allows one cartoning machine to handle everything from compact cosmetic tubes to larger pharmaceutical packs, maintaining consistent precision across the entire range of products. Its configuration range accommodates cartons from 70 to 240 mm in length, 20 to 90 mm in width, and 15 to 55 mm in height, covering the most common format requirements across both cosmetic and pharmaceutical lines.

Ergonomic features for everyday operations

The NC 100’s carton magazine has been positioned for straightforward, comfortable access, making the loading process efficient and smooth. This ergonomic consideration supports operators in maintaining a steady workflow, shift after shift.

Built on expertise and global reach

With over 90 years of experience, Norden has been shaping the evolution of tube packaging since 1934, when its very first tube filling machine was delivered. Since then, the company has supplied more than 8,000 machines, with 130 to 150 units delivered every year, serving a constantly expanding customer base.

Today, Norden supports customers in more than 60 countries, with the majority of its machines exported worldwide. This international presence ensures that customers benefit not only from advanced equipment like the NC 100 but also from a network of knowledge and support that extends across every major market.

A reliable platform for modern cartoning

The NC 100 unites speed, adaptability and robust design in a single solution, allowing manufacturers to meet diverse packaging demands without disrupting production flow. Its flexibility, rapid changeovers and durable construction make it an essential resource for companies aiming to optimize their packaging processes while maintaining consistent quality.

Discover the NC 100 cartoning machine in detail.