Shift to a new production level

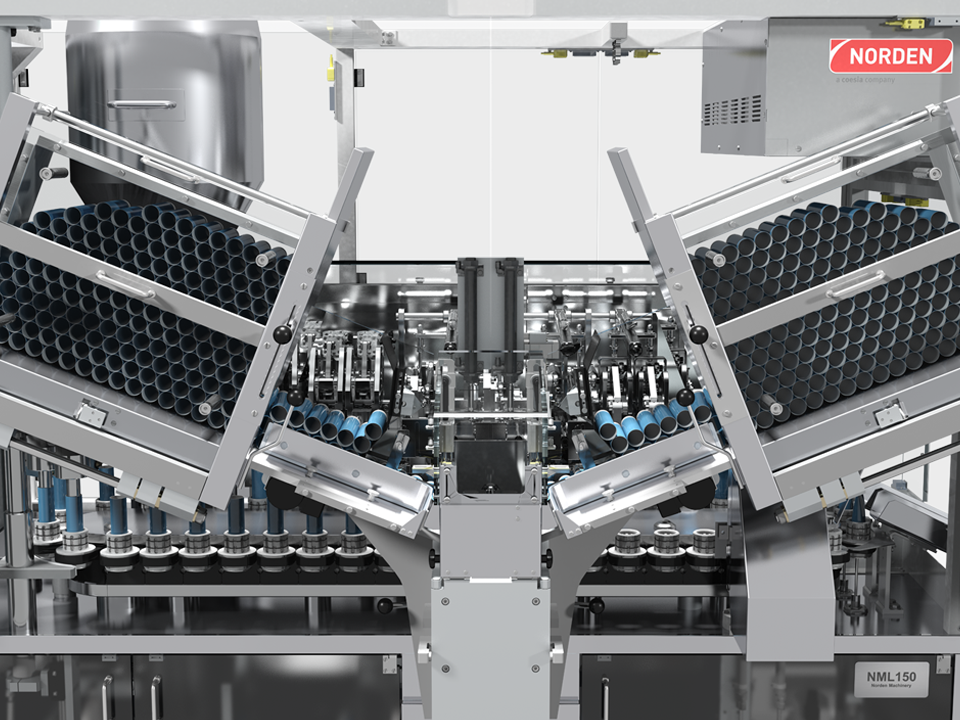

Built for growing production needs, the NML 150 tube filler delivers reliable Norden quality in a cost-effective package—perfect for manufacturers ready to level up.

- Filling up to 150 tubes per minute

- 90+ years of Norden experience inside

- Convenient service and maintenance

- Upgrades available to keep you competitive

- A modern set up the new generation control system Norden EasyWare II

- Global service network

- The parts you need, when you need them

- Production reports, including OEE-data

Please note: The NML 150 is not available for customers in Europe and North America.